Electromagnetic Mobile Clutches

for Pumps and Compressors

MOBILE ELECTROMAGNETIC CLUTCHES

For Pumps and Compressors

Ogura mobile electric clutches provide reliable performance in applications where long life and no maintenance is critical. These clutches were primarily designed as air conditioning compressor clutches, but now are also used as clutches for hydraulic pumps (clutch pump), high pressure piston pumps, vacuum pumps and centrifugal pumps. The units that are used to clutch hydraulic pumps and to clutch water pumps are typically used for tow trucks, marine winch drives, and boom trucks in the utilities industry.

Pumps handling liquid are typically driven by our clutches from a gas engine on such equipment as water jetters, pressure washers, street sweepers and carpet cleaning trucks. Pump clutches are often used on vacuum pumps and compressor applications such as refrigeration and waste removal trucks as well as mobile service trucks, or “under hood” applications where the clutch engages an air compressor mounted in the engine compartment of a service truck.

Ogura mobile clutches range in size from 58 to 1500 lbs-ft and feature numerous pulley configurations including v-belt and poly-v as well as universal hub mounts. The user can choose from a straight, splined or tapered bore to match the corresponding pump shaft. Many of our older pump and compressor clutch configurations are interchangeable with competitor models.

How Mobile Electromagnetic Clutches Work

Principles of Operation

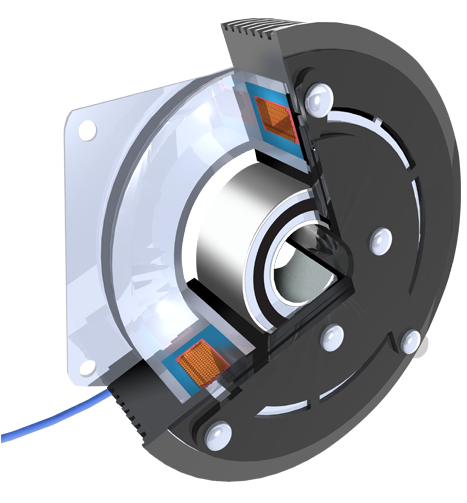

Mobile clutches are made up of three major sub-assemblies.

Field assembly. This is the coil and backing flange which provides the magnetic flux that makes the clutch engage.

Rotor assembly. This includes the pulley and the bearing and is normally the input of the clutch.

Armature assembly. This includes the armature disc, springs and hub and is normally the output.

The field is mounted to a stationary member such as a support bracket of a pump. The rotor is driven by the belt from the engine and rotates constantly. When the clutch is energized, the armature pulls against the rotor and drives the shaft of the pump.

Engagement of the armature to the rotor is caused by the magnetic attraction between these two elements. The section below shows how the magnetic field is created when direct current is applied to the field. The magnetic flux is transferred from the field into the rotor and then into the armature. The slots in the rotor and the armature are called banana slots. These slots allow the flux to contact the rotor and the armature in more than just two places. [A normal magnet has only two points (north and south) of attraction.] By making multiple points of flux connection, the torque of a clutch can be increased. The picture below shows a standard mobile clutch. It has two flux paths. This is called a double flux, or a four-pole design. To disengage the clutch, the voltage going to the coil is simply turned off. Once the voltage is released, the springs between the armature and the hub pull the armature away from the rotor, creating an air gap so no contact is made.

Reasons To Use Mobile Clutches

Reduced horsepower consumption from the engine

Since the pump is not required to run all the time, especially over the road, there is less wasted power.

Extended pump life

Since the clutch allows the pump to be disengaged, life is greatly extended because the pump is not rotating when it is not being used.

Less cost

Since the pump only runs when needed, fuel is saved. Also, the pump does not need to be replaced as often.

Simple installation

Since the clutch runs directly off the battery, all that is required is a basic switch to engage and disengage the clutch.

Operator convenience

Rather than a mechanical linkage which can cause an additional force required by an operator to engage a clutch, an electric clutch is engaged by a simple flip of a switch. Because the clutch is engaged electrically, this switch can be incorporated into a control panel so the operator does not have to be in the same location as the clutch when it engages.

Cold weather starting

By using a clutch, the load is not engaged at start up. This allows the engine to come up to full efficiency before engaging the clutch.

Ogura Design Advantages

Solid forged rotor

A one piece solid forged rotor means no chance of internal parts separation. Our rotors also have an even wall thickness around the coil which gives optimum flux distribution, maximizing torque.

Different coil voltages available

Although 12 volt is the most common, 24 volts can also be made available. Depending upon the quantity, other specialty voltages can be made

High temperature, longer life grease

All models include our special long life grease which has shown a significant improvement in life over other standard high temp greases.

E-coating

Where possible, all parts in the clutch are e-coated to give maximum corrosion protection.

High temperature epoxy coil

To help prevent failure from both vibration and outside contaminants, all coils are sealed in the coil shell with a high temperature epoxy coating.

Forged machined pulley

All models in this section use a heavy duty machined pulley. A stronger pulley resists damage due to abusive environments.